.png)

This legislation, which amends the 'Machinery Directive' of 2006, was approved last June after a complex negotiation process initiated in 2021. For manufacturers of agricultural machinery, the Regulation will come into force on January 20, 2027. But what does this mean for farmers and contractors who use these machines?

The main innovations concern specific rules on digital technologies such as artificial intelligence and cybersecurity. The new European Regulation introduces many changes for the marketing of new machinery, but important innovations also come for automation and new technologies, until recently considered futuristic.

Before we get into the specifics, the key thing to know upfront is this: The Commission has opted for a Regulation over a directive as a legislative instrument to ensure uniform application across the various member states of the European Union.

The Regulation has already come into force, but for manufacturers of agricultural machinery, it will only become binding from January 20, 2027. Therefore, until that date, machinery must be placed on the market in accordance with Directive 2006/42/EC.

In contrast to the previous document, which required implementation through national Regulations, the new Regulation will be directly applicable and binding without the need for further transpositions by the member states.

The objective is to provide a clear and detailed regulatory framework that can meet the needs of sectors undergoing continuous technological evolution, while ensuring uniformity among all EU member states.

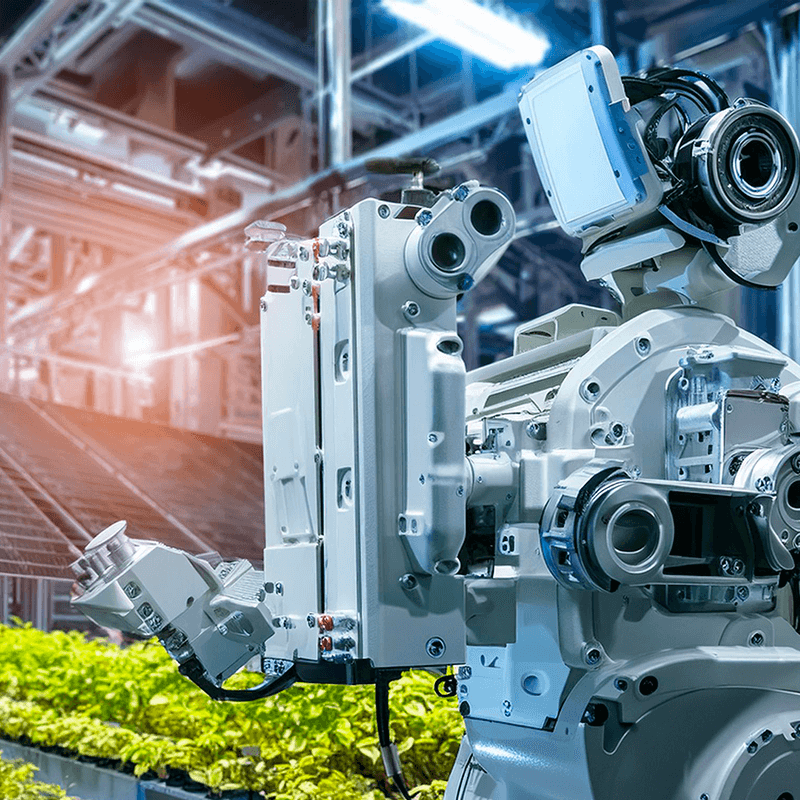

The new Regulation introduces several changes that will have a significant impact on the future of agricultural mechanisation. In a context where these aspects were not previously covered by Regulations, issues related to automation and robotics are now emerging. Among the safety components listed in the Regulation, we now find all those systems "with fully or partially self-evolving behaviour that use automatic learning approaches." Essentially, these are all elements that, to improve the operational safety of machinery, harness the potential of machine learning (ML) and artificial intelligence (AI).

Perhaps the most significant introduction concerns autonomous mobile machines, which provide all the necessary safety functions during movement and operations without constant operator intervention. These autonomous machines utilise artificial intelligence and machine learning. Because of this, they are considered high-risk and must be certified by an external body before being placed on the market. It's important to emphasise that the risks associated with these machines can change over time due to their self-evolving behaviour; therefore, it's essential to design them to function with varying levels of autonomy.

To ensure safety, agricultural robots in the field must remain within predefined zones and record all data related to the decisions made, storing them for at least one year. Operators must be able to intervene in real-time to correct any errors. The Regulation also introduces two new definitions: the supervisor, responsible for machine supervision, and the supervision, which allows remote control via a device. The machine cannot operate without active supervision and must inform the supervisor of any anomalies.

Furthermore, the Regulation considers human-machine interaction in the field. This includes risks such as psychological stress related to sharing a workspace with robots. Manufacturers must adapt their machines to communicate with operators comprehensibly, both verbally and non-verbally, and must be equipped with devices to always detect people and obstacles, even during non-operational movements.

The Regulation also addresses new concepts, such as attention to human-machine interaction in the field, considering the risks and psychological stress arising from shared workspace. According to the provisions, manufacturers must adapt their machines to communicate effectively with people, both verbally and through gestures or expressions, and provide understandable explanations of planned actions. Additionally, mobile machines must be equipped with devices for detecting people and obstacles that are always active, during both operational activities and non-operational movements, such as returning to the charging or parking station.